Our Infrastructure

Corn Wet Milling Unit

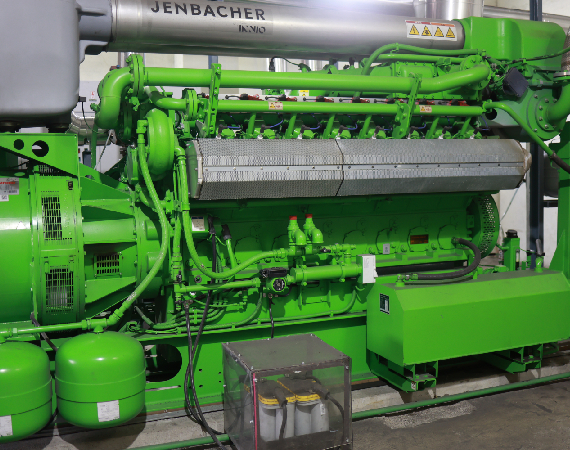

HFDL maize wet-milling factory is set up in an eco-friendly environment with best of breed infrastructure. The plant spans over the massive area of 202343 sq. m., wherein 36,500 sq. m. area is entirely apportioned to preserve a Green Buffer Zone. The quality control cells at the unit is manned by the qualified staff and equipped with Wet Labs,Instrumentation Labs and Microbiology Labs to carry intermediate, in process and final product analysis. Our quality control professionals monitor all the stages discreetly, right from the manufacturing, processing to the warehousing and packaging of the products To benchmark our food safety & quality standards, we engage stainless-steel machinery for processing the corn, store the procured corn in full stainless-steel silos and further steep them in fully-SS Vats. It allows us to retain purity & enhance shelf life of the produce. Effluent Treatment Plants is set up to methodically handle the waste-water emissions in the form of high volumes of biochemical oxygen demand and suspended solids. With anaerobic digester, our factory unit is maintaining an eco-friendly point to seamlessly produce methane gas and make it available for reuse in the boiler. Our grinding capacity accumulates to 300 MT per day, resulting in the daily production of: 200 MT of Maize Starch Powder, 30 MT of Maltodextrin powder, 13.5 MT of Corn Gluten, 16.5 MT of Corn Germ and 24MT of Dry–Fibre respectively.

© 2022 Himalayan Foods All Rights Reserved | Designed & Developed By India Websoft

payment success

Your order has been successfully processed! Please direct any questions you have to the store owner. Thanks for shopping

continue browsing